Mit Rubber And Plastic Technology

There is a good scope for rubber and plastics technologists in india as well as abroad.

Mit rubber and plastic technology. We aim to impart high technical knowledge practical skill leadership qualities ethical skill leader and foster creative entrepreneurial skill to become a demand. Percapita consumption of plastics in india is very low about 7 5 kg when compared with world average about 25kg. Freely browse and use ocw materials at your own pace. The department of rubber plastics technology shall strive to be a globally renowned department known for its academic excellence professionalism and social responsibilities.

Thermosets which include epoxies polyurethanes and rubber used for tires are found in many products that have to be durable and heat resistant such as cars or electrical appliances. Get hands on experience in one of the top plastics technology centers in the nation for research development and education related to injection. Master the major plastic processes and take the lead as a process design or research engineer. There s no signup and no start or end dates.

Visit the links in the left menu or the video links at the bottom of this page for more information on the rubber program. The department of rubber and plastics technology was started in the year 1988 and offers a four year degree programme in b tech rubber and plastics technology and a two year programme degree program in m tech rubber technology besides m s. By research and ph d program in the field of polymer science and technology. Knowledge is your reward.

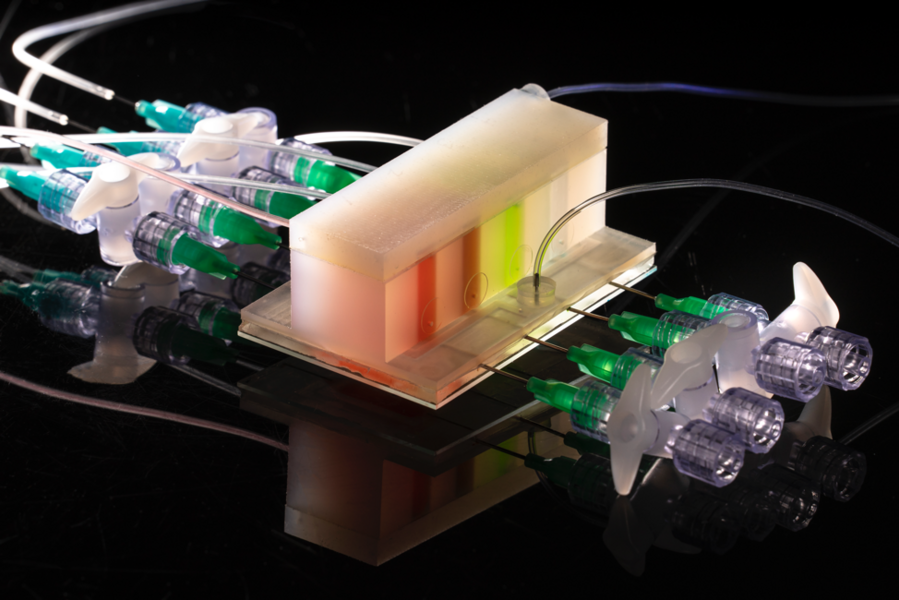

No enrollment or registration. Degrees in rubber engineering technology in the world. In the mit and dow materials engineering contest madmec student teams design and prototype devices to harness store and exploit alternative energy sources. So there is a lot for polymer engineers to.

Use ocw to guide your own life long learning or to teach others. One drawback to these materials is that they typically cannot be easily recycled or broken down after use because the chemical bonds holding them together are. With support from the lord foundation the purchase of advanced equipment will allow us to build custom experimental equipment develop and test prototypes and even make a new part for. Inventions why this 3 d printed rubber material could save the drone industry researchers at mit have found a way to print components that cause less damage in the event of a crash.

Like the plastics program rubber graduates are among the university s most heavily recruited as ferris offers one of the few b s. Mit opencourseware is a free open publication of material from thousands of mit courses covering the entire mit curriculum.